What is IHS?

IHS uses a simple and effective concept, supplying water at an “amplified” air flow, much more than what is actually need to carry the water into the environment, and spray the water in that flow directly in the environment, the right quantity necessary for the humidification process, but less quantity compared to the total air volume in circulation, thus, very far from its saturation point and probable condensation.

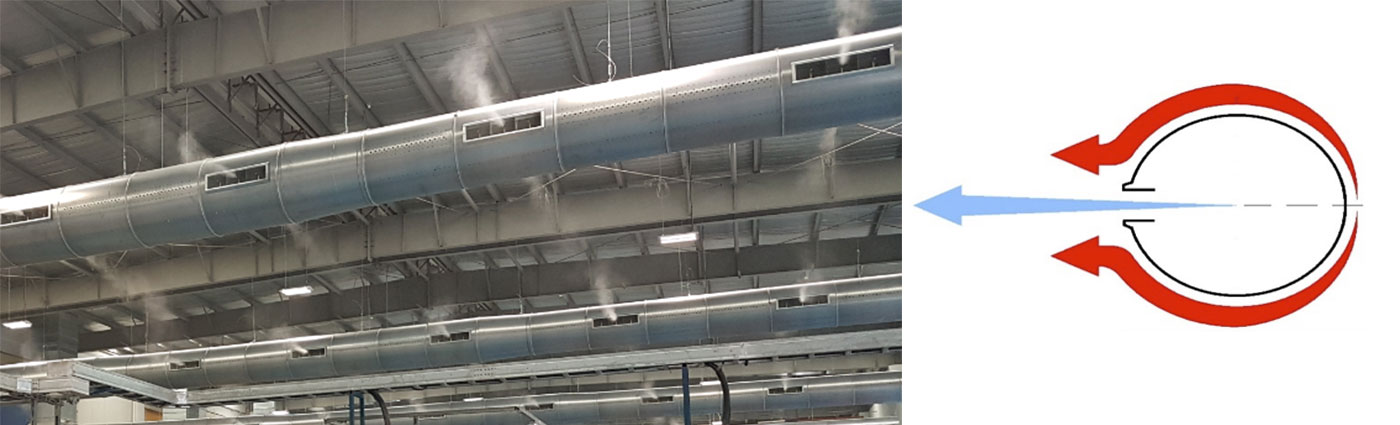

IHS has special air diffusion ducts into the environment, with a circular cross-section, experimentally dimensioned to create an inductive ambient air recall effect, hot and dry, and near it a fine aerosol of sprayed water is put in the flow.

IHS inductive ducts are composed of a circular duct which has, especially concentrated in the upper part, a series of small holes where the air used for propulsion comes out at a speed that creates areas of vacuum (pressure lower than ambient pressure) on the sides of the holes.

These micro-vacuums attract a volume of hot and dry air present in the department near the IHS duct with a ratio, verified through testing on created prototypes equal to 1/10. This means that, if 10 is the quantity of air introduced into the departments by the Ventilation System, the total quantity of air that will be moved near the IHS inductive duct will be at least 10 times, thus equal to 100.

Therefore, this volume of air if brought to saturation (98% RH) will be able to carry into the environment 10 times the quantity of water needed for the humidification process, or, otherwise, it will be necessary to use injection air from the ventilation system equal to only 1/10 of what is needed by a traditional saturation System.

Benefits